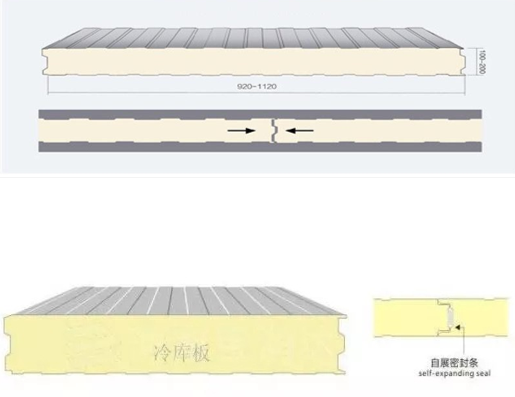

Delida polyurethane cold storage board has excellent thermal insulation performance, good mechanical properties, simple structure, fast installation, beautiful appearance, classic and durable. It is specially designed for cold storage and cold storage, with thickness of 100, 120, 150, 200, 250, etc.

Performance description:

1. The concave convex groove structure improves the insulation and air tightness of the plate joints, which is specially designed for refrigerators and warehouses;

2. The board is uniform and stable, with excellent heat insulation performance and waterproof performance;

3. Light weight and beautiful appearance can effectively solve the temperature difference in refrigeration industry;

4. Within a certain modulus, the library body can be freely changed in the three directions of length, width and height, and can be expanded or reduced according to the needs. The assembly plate can also be disassembled and reassembled in different places, so the installation is simple and fast.

♦ Core advantage

Energy saving and heat preservation

The closed cell rate of the core material is more than or equal to 97%, and the heat insulation performance is superior

Fire retardant

The product has good fire resistance

Airtight and sound insulation

It has good sound absorption and can reduce the sound caused by the impact of rain and hail

Green environmental protection

Formaldehyde free, free from microbial invasion, recyclable

Aesthetic economy

The surface has various forms and rich colors; Reduce material loss, save construction time and project cost

♦ Cold storage is divided into the following three categories

1. Fresh keeping warehouse (the temperature of fresh keeping warehouse is kept at 0 ℃, and the recommended thickness of cold storage board is 10 cm)

The fresh-keeping storehouse keeps the original quality and freshness of some agricultural products to a large extent, that is, the fresh agricultural products are still fresh or close to the fresh state and quality when they are just picked after a period of fresh-keeping storage.

2. Cold storage (the temperature of cold storage should be kept at - 18 ℃, and the suitable thickness of cold storage plate should be 15 cm)

The cold storage is mainly used for constant temperature storage of food, dairy products, meat, aquatic products, poultry, fruits and vegetables, cold drinks, flowers, green plants, tea, drugs, chemical raw materials, electronic instruments, etc.

3. Freezer (the temperature of the freezer is kept at - 38 ℃, and the suitable thickness of the freezer plate is 20cm)

Freezer freezer is mainly used for food, medicine, mechanical freezing processing and refrigeration. It can keep a certain low temperature through artificial refrigeration.

The technology content of multi-storey civil cold storage is low, the temperature control range is small, the related facilities are not matched, and some of them are old and aging. From the system and scope of application, they belong to meat, aquatic products, fruits and vegetables enterprises, and the efficiency of enterprise self operation cold storage is not high.

Medical cold storage, also known as medicine cold storage, is widely used for the storage of various drugs, vaccines, blood, plasma, pharmaceuticals, reagents, stem cells, bone marrow, biological products and other medical supplies. The thermal insulation material of the storehouse plate is generally polyurethane double-sided plastic coated color steel plate, which has the advantages of light weight, good heat insulation performance, safety and environmental protection, strong hardness, corrosion resistance, etc., and adopts foam integrated molding, so it is one of the better materials for the selection of the cold storehouse plate.

Process technology:

Advanced level of large-scale production line and intermittent production equipment, strong productivity, good quality, fast

Advanced manufacturing technology: automatic continuous production equipment, mainly series computer automatic control, high production efficiency.

Light weight: polyurethane sandwich board only weighs 10-14 kg per square meter

Good thermal insulation

Good overall stiffness and high bearing capacity: because the polyurethane core material is foamed into blocks, after the chemical reaction is stable, the sheet is cut according to different thickness, and then bonded with the color steel plate, which has the characteristics of smooth surface, stable performance and good integrity.

簡體(tǐ)中(zhōng)文(wén)

簡體(tǐ)中(zhōng)文(wén)

Recruitment Hotline

Recruitment Hotline